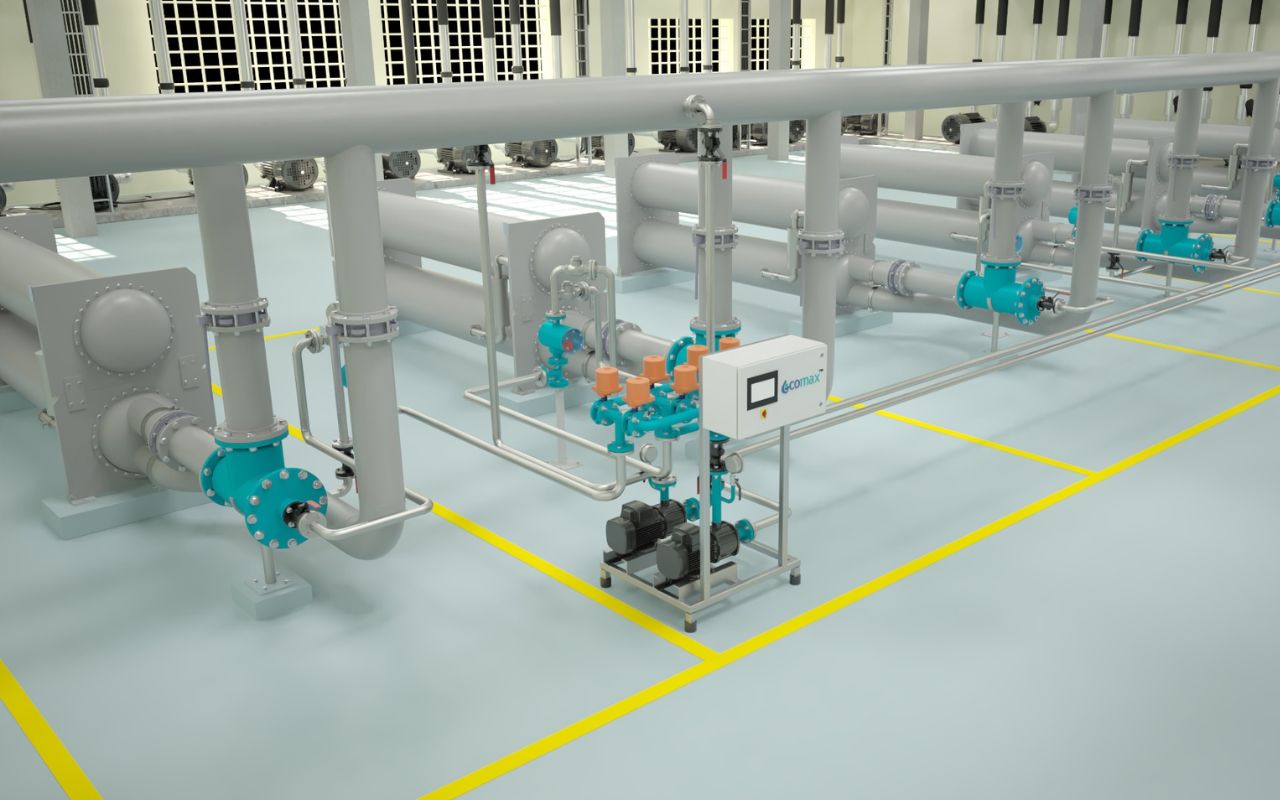

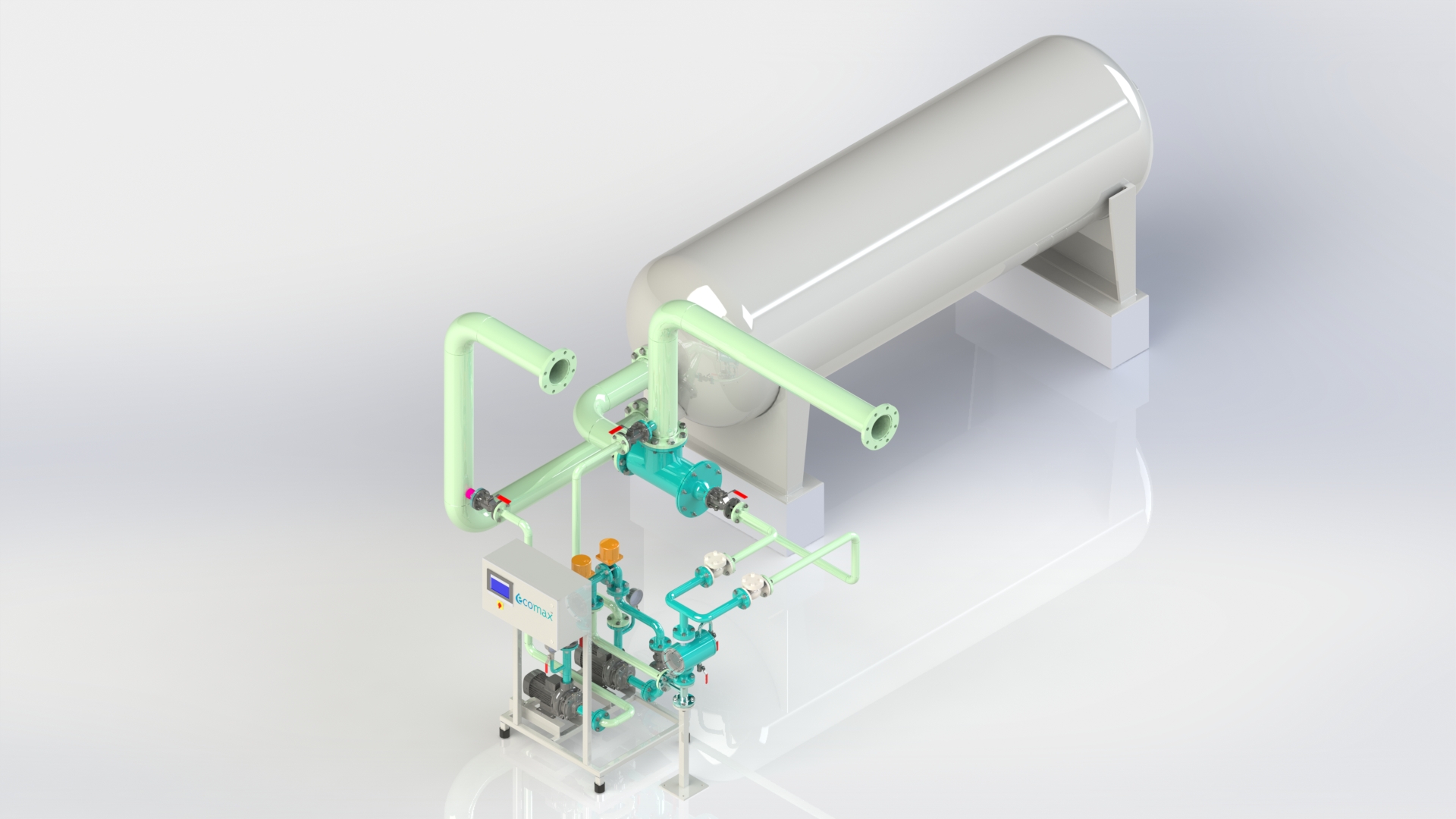

What is an Online Automatic Tube Cleaning System?

An online automatic tube cleaning system is a type of equipment used for cleaning the interior of tubes, pipes, and heat exchanger tubes in various industrial and commercial applications. This system helps to keep the tubes clean online and help improve heat transfer, thereby improves chiller efficiency and reduces chiller power consumption. These type of systems use cleaning sponge balls made of natural rubber with special composition and circulation of these cleaning balls into the condenser/heat exchanger tubes help clean the tubes while the equipment like chiller is in operation.

Condenser cleaning balls, also known as condenser tubes cleaning balls or chiller maintenance balls, are an integral part of online tube cleaning systems in HVAC industry. These condenser cleaning sponge balls are used to maintain the efficiency of chiller systems.

The efficiency of water cooled chillers reduces over time due to accumulation of dirt, scaling, biofouling and other contaminants in the condenser tubes. The condenser cleaning balls are used to clean the inside of the tubes by gently scrubbing the inside of the tubes as the fluid flows through the system. This regular cleaning helps to ensure the long-term reliability and efficiency of the chiller system, reducing the risk of breakdowns, improving energy efficiency, and extending the life of the equipment.

How does condenser cleaning balls work?

Condenser cleaning balls work by using a physical scrubbing action to clean the interior of the condenser tubes. The cleaning balls are typically made of a soft, flexible material, such as sponge or rubber, and are designed to be inserted into the fluid flow in the chiller system.

As the fluid flows through the condenser tubes, the cleaning balls move along with the fluid and gently scrub the inside of the tubes, removing any dirt, debris, or other contaminants that have accumulated over time.

The frequency and duration of cleaning with the cleaning balls is determined by a variety of factors, including the type of fluid being used in the system, the type of contaminants present, and the overall efficiency of the system. Regular cleaning with the cleaning balls can help to maintain the efficiency of the chiller system and reduce the risk of breakdowns and repairs, while also extending the life of the equipment.

Regular cleaning with cleaning balls can help to maintain the efficiency of the chiller system, reduce the risk of breakdowns and repairs, and extend the life of the equipment.

What are the advantages of using condenser-cleaning balls over other ways?

Condenser cleaning balls have several advantages over other methods of cleaning condenser tubes:

Convenience: Cleaning with condenser cleaning balls is simple and convenient. The balls can be easily inserted into the fluid flow, and the cleaning process is automated, with no need for manual intervention.

Effectiveness: Cleaning balls are highly effective at removing dirt, debris, and other contaminants that can build up on the inside of condenser tubes. The physical scrubbing action of the balls is effective at removing the soft scale and reducing fouling.

Gentle cleaning action: Cleaning balls are typically made of a soft, flexible material that is gentle on the delicate surface of the condenser tubes. This helps to reduce the risk of damage to the tubes and prolong the life of the equipment.

Improved efficiency: Regular cleaning with cleaning balls helps to maintain the efficiency of the chiller system by removing contaminants that can reduce heat transfer efficiency. This can result in lower energy costs, reduce carbon footprint, improved system performance, and reduced downtime.

Cost-effective: Cleaning with condenser cleaning balls is a cost-effective method of maintaining the efficiency of chiller systems. It is a relatively low-cost solution compared to other methods, and can help to reduce the need for more expensive repairs and maintenance.

Conclusion:

Online Condenser Cleaning Balls Systems are a convenient, effective, and cost-effective solution for maintaining the efficiency of chiller systems. These systems can help achieve Net Zero goals of the organizations. They have several advantages over other methods of cleaning condenser tubes, including convenience, effectiveness, gentle cleaning action, improved efficiency, and cost-effectiveness. The frequency and duration of cleaning with the cleaning balls is determined by various factors, including the type of fluid being used in the chiller system, the type of contaminants present, and the overall efficiency of the system.